Our amazing partner HPTec continues to innovate and develop new products to help their customers produce high-quality products with a long working-life. We are proud to feature some of HPTec's newest tools, the drill type 271, 243, and tapered 596 drill for microvias.

Your demand for quality is our obligation.

New Drills From HPTec

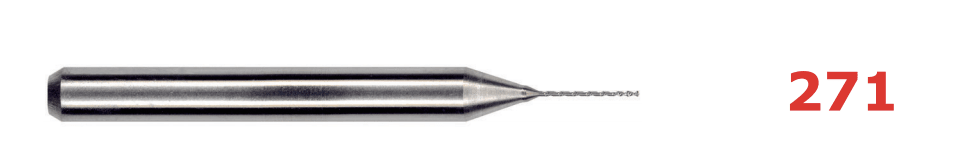

Type 271

Type 271 is a specially designed, multilayer drill, spade type version, featuring a new tool design named: two in one flute. A double spiral increases the stability of the tool while creating a large chip pocket for the removal of the chips. This has been designed to increase the performance of the drill with improved life cycles through three regrinding cycles. It features improved drill stability, reduced breakage rate, higher positioning accuracy. With excellent repeatable hole wall quality through reduced nail heading and hole wall roughness. Reducing burring and a very good debris evacuation equate to lower bit cutting temperatures. The latest solid carbide developments have been included in the complete development of the tool. Thus 271 is also suitable for highly abrasive base materials, such as High Tg and Rogers ceramic.

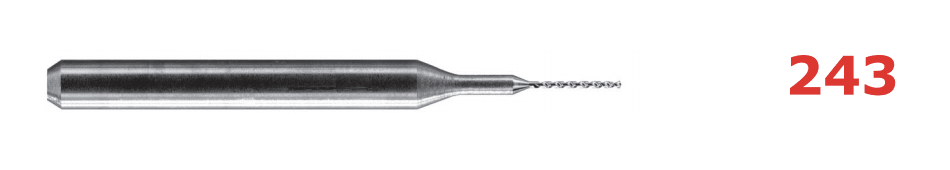

Type 243

The advantage of this new drill is its very wide range of application due to a significant increase in the performance of the drill, resulting from positioning accuracy and less deviation during the complete lifetime, including three regrinding cycles.

Breakage rate is 20% lower; higher feed rates; wear is 10% lower; hole wall roughness, nail heading, and burring are all reduced. Optimize your drill deviation with significant reduction in tool wear, and cost while achieving an improved surface quality hole wall. The type 273 drill is also suitable for highly abrasive base materials, such as High Tg and Rogers ceramic.

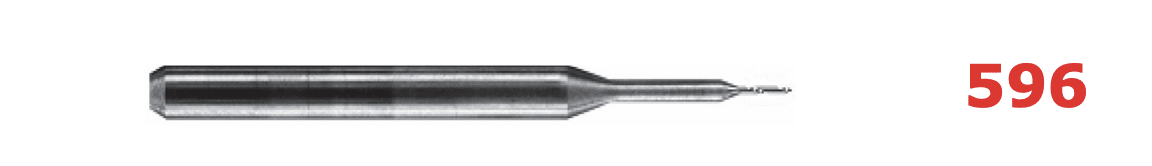

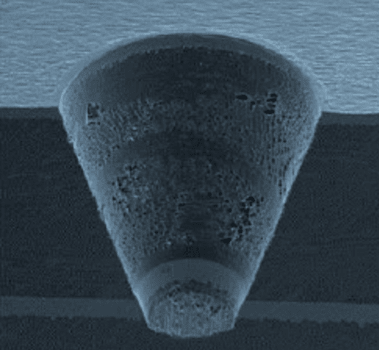

Tapered 596 Drill for Microvias

The advanced Microvia drill has a tapered outer diameter for drilling micro via, blind holes with tapered walls. It enhances high hole quality, high position accuracy, and economical drilling compared to laser when used on multi-spindle machines.

HPTec has been in business for over 40 years, as a true market leader, specializing in high technology tools from micro drills to diamond coated routers. Their unique, advanced, drilling tools makes HPTec one of the product lines that TFE is proud to represent. For more information, visit www.hptec.de.