Our goal at Aismalibar is to bring our customers the best possible solutions from best possible suppliers. We feel it’s our responsibility to do this. In this Tech Bulletin we are pleased to highlight a recent testing exercise we performed constant AC and DC testing of Aismalibar HT 2.2 and HTC 3.2 Thermally conducted printed circuit material. And frankly we could not have been more pleased with the results. Check this out below.

Constant AC and DC, high voltage testing of Aismalibar HTC 2.2 and HTC 3.2, thermally conductive printed circuit material.

Test Coupons:

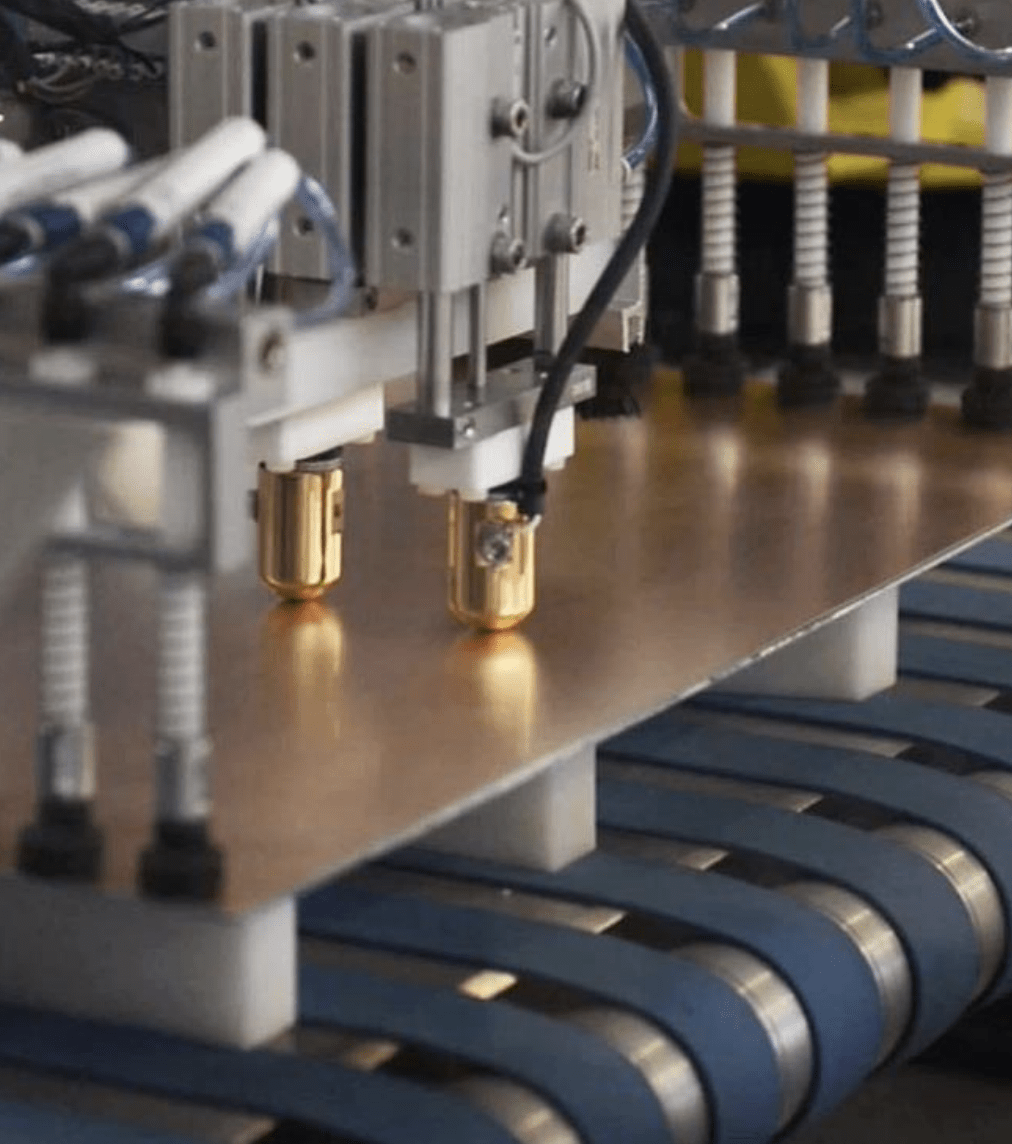

Layer 1 consisted of 2.0” x 2.0” squares. Layer 2 was smaller 1.8” x 1.8” squares to prevent edge arc. The coupons were laid up on a 18” x 24” panel, etched and processed as normal. There was 70 total coupons per panel.

The material tested was highly thermally conductive thin core HTC 2.2 and HTC 3.2, laminate manufactured by Aismalibar. Five panels of different thickness material were prepared from 100 μm to 210 μm, in both 2.2 w and 3.2 w material. The electrical arc dielectric test was performed using a Vitrek V61 AC/DC Safety Analyzer. Set Points: Max Amp at 0.10mA, Ramp set at 10sec, test time max capability 120sec, V DC max at 6kV, AC max at 5kV.

Results:

All materials were tested repeatedly, with no failures to our maximum voltage output, with continuous voltages of 5000VAC and 6000VDC, for two minutes each. To further stress the materials, the thinnest samples were tested continuously for three hundred minutes, using repeated cycling resulting in no failures and no detectable material degradation.

Summary:

Maximum continuous voltage, dielectric capability of the Aismalibar substrates was significantly above the test voltage of the equipment used. The HTC2.2, HTC3.2 and 3.2W 180Tg substrate can effortlessly handle 5000VAC and 6000VDC for three hundred minutes at ambient conditions, making the laminate suitable for high reliability and high voltage applications.