Introducing: Thermal Interface Materials

Ah, heat management. A problem that, despite years of progress, still needs a more ideal solution. Furthermore, In the last few years there has also been an explosion in the need for, and use of, power electronics devices such as A-D and D-A converters in service of the shift to electric vehicles. Having a solution to this vexing problem is of paramount importance to many OEMs. With this in mind, we are excited to present a reliable solution through our partner Aismalibar, a premier supplier of thermal management materials.

Improving Dielectric Isolation and Fast Thermal Transmission

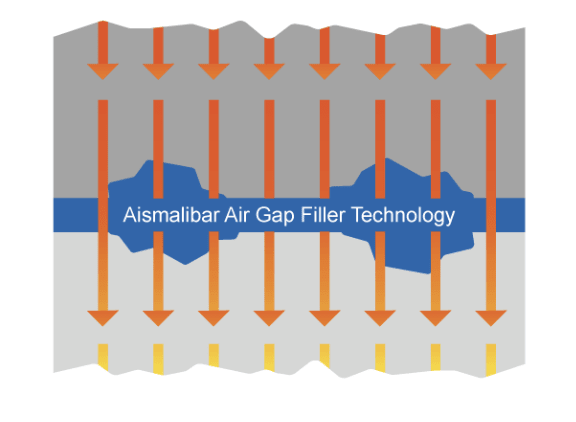

Air Gap Filler Technology

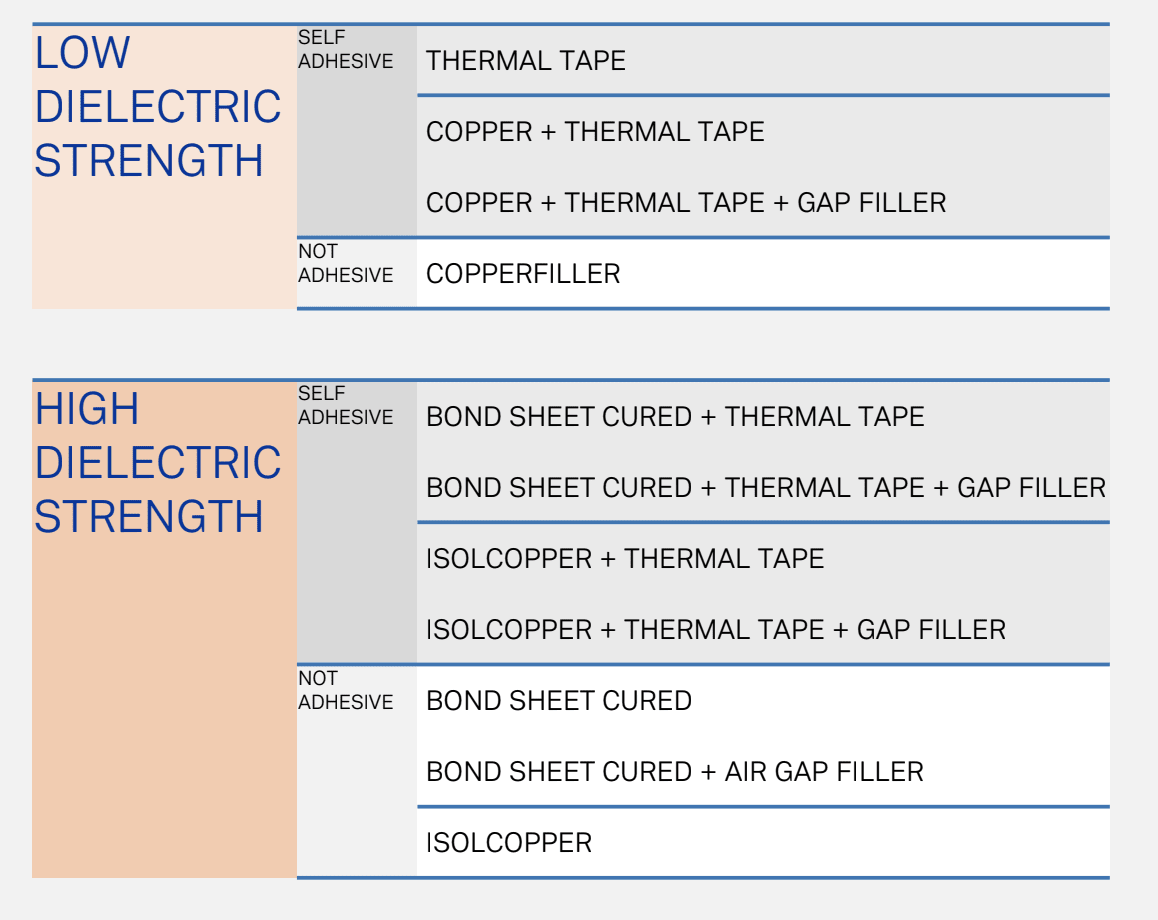

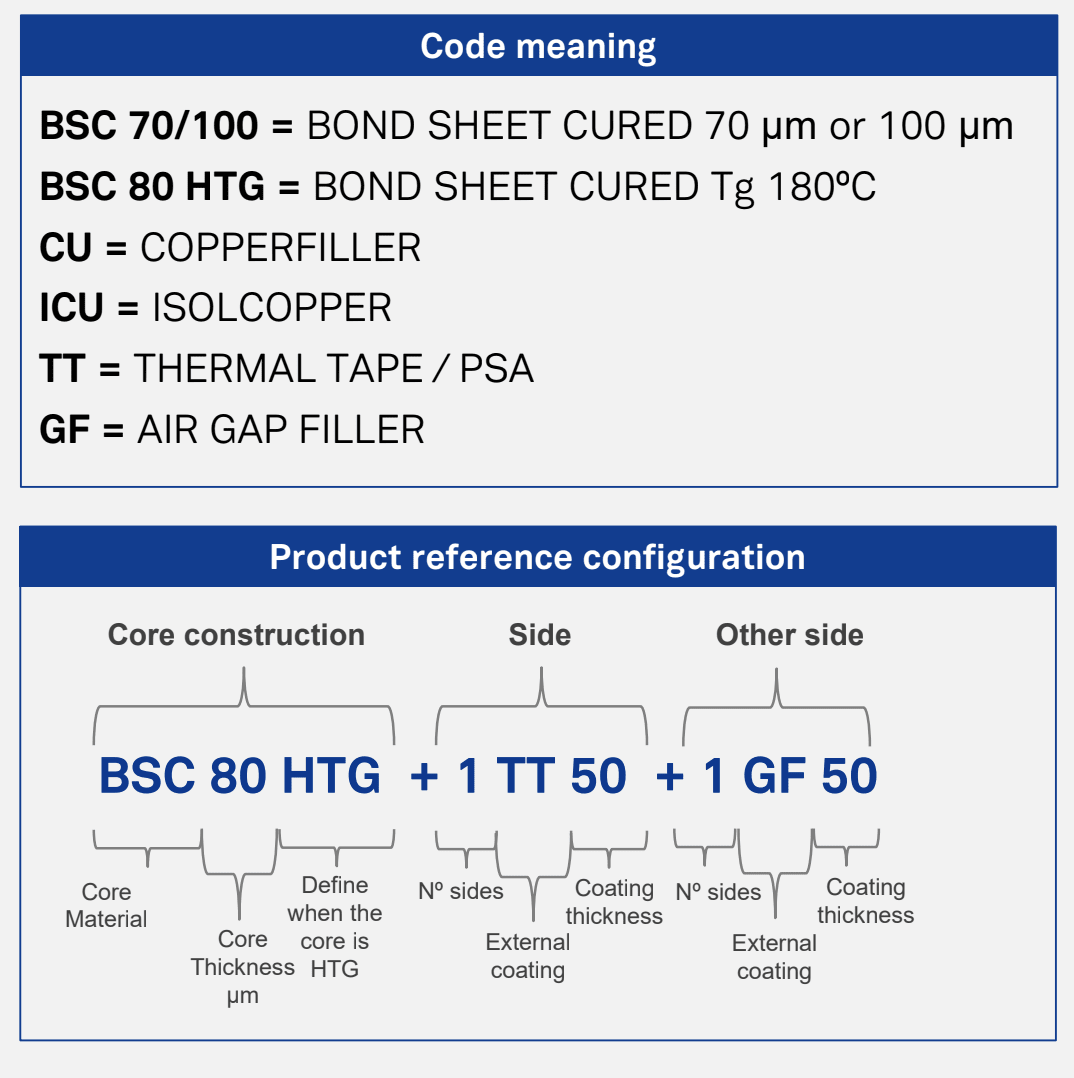

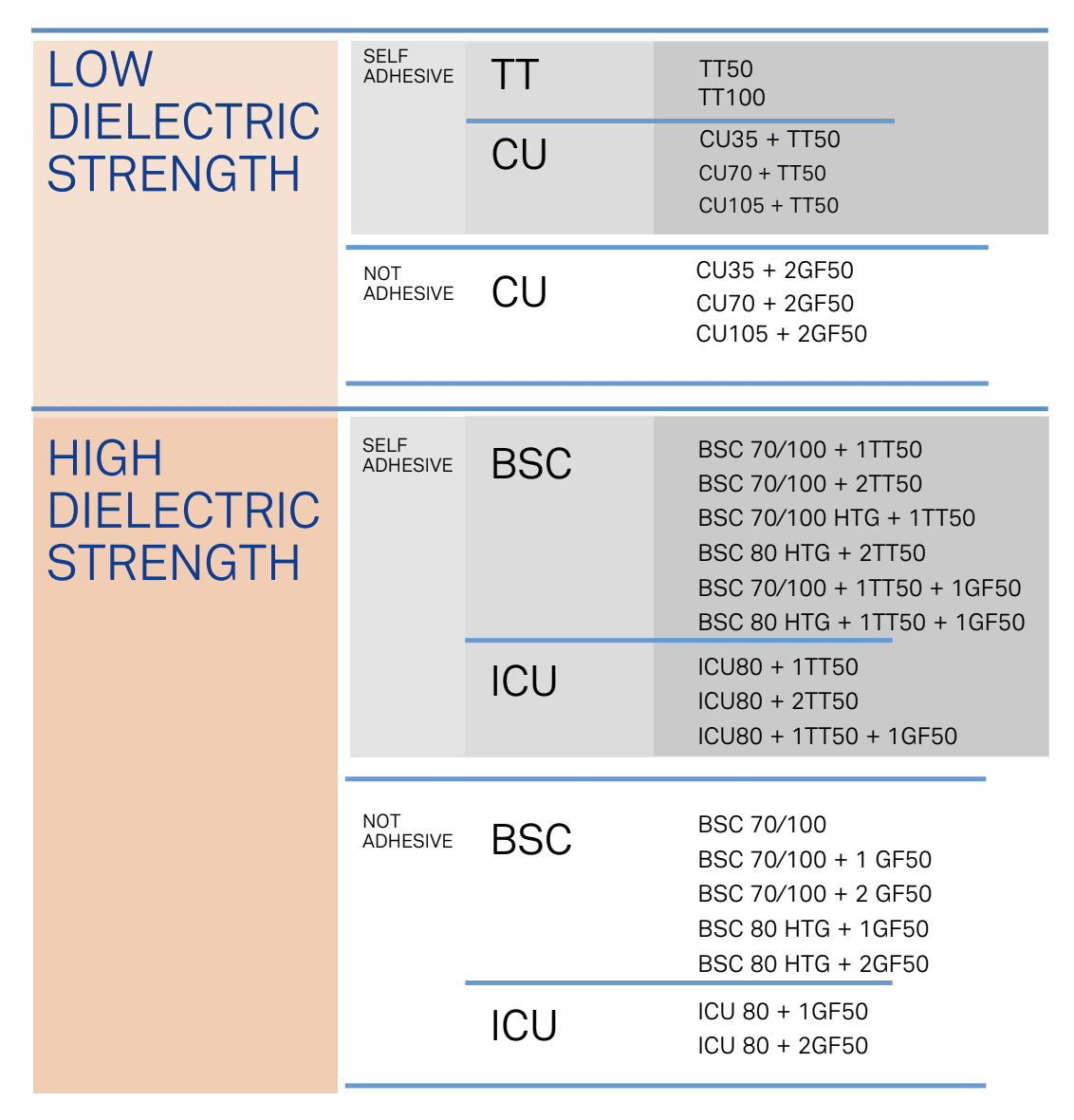

Aismalibar Thermal Interface Materials (TIMs) are divided into two main areas differentiated based on whether or not they need dielectric capacity. Dielectric requirement is determined by the electronic device, its operating voltage, and the applicable regulations regarding ground insulation.

Aismalibar Thermal Interface Materials (TIMs) are divided into two main areas differentiated based on whether or not they need dielectric capacity. Dielectric requirement is determined by the electronic device, its operating voltage, and the applicable regulations regarding ground insulation.

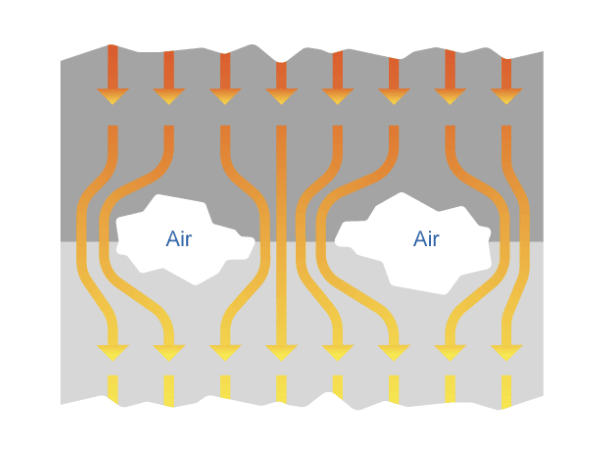

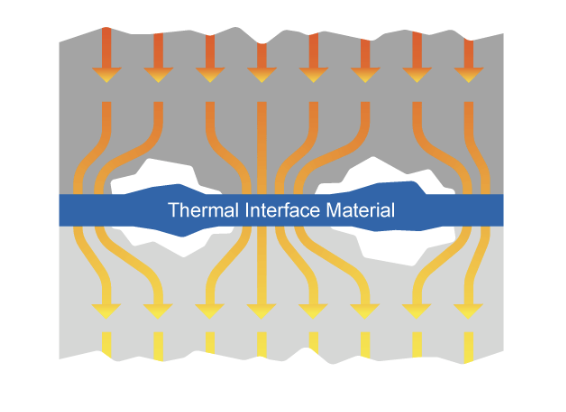

Aismalibar has additionally developed a series of applicable surfaces on our TIMs, differentiated by whether or not they need to be self-adhesive. Both surfaces serve, in turn, to reduce the air cavities that exist between the surfaces of the TIMs and the heatsinks or electronic components.

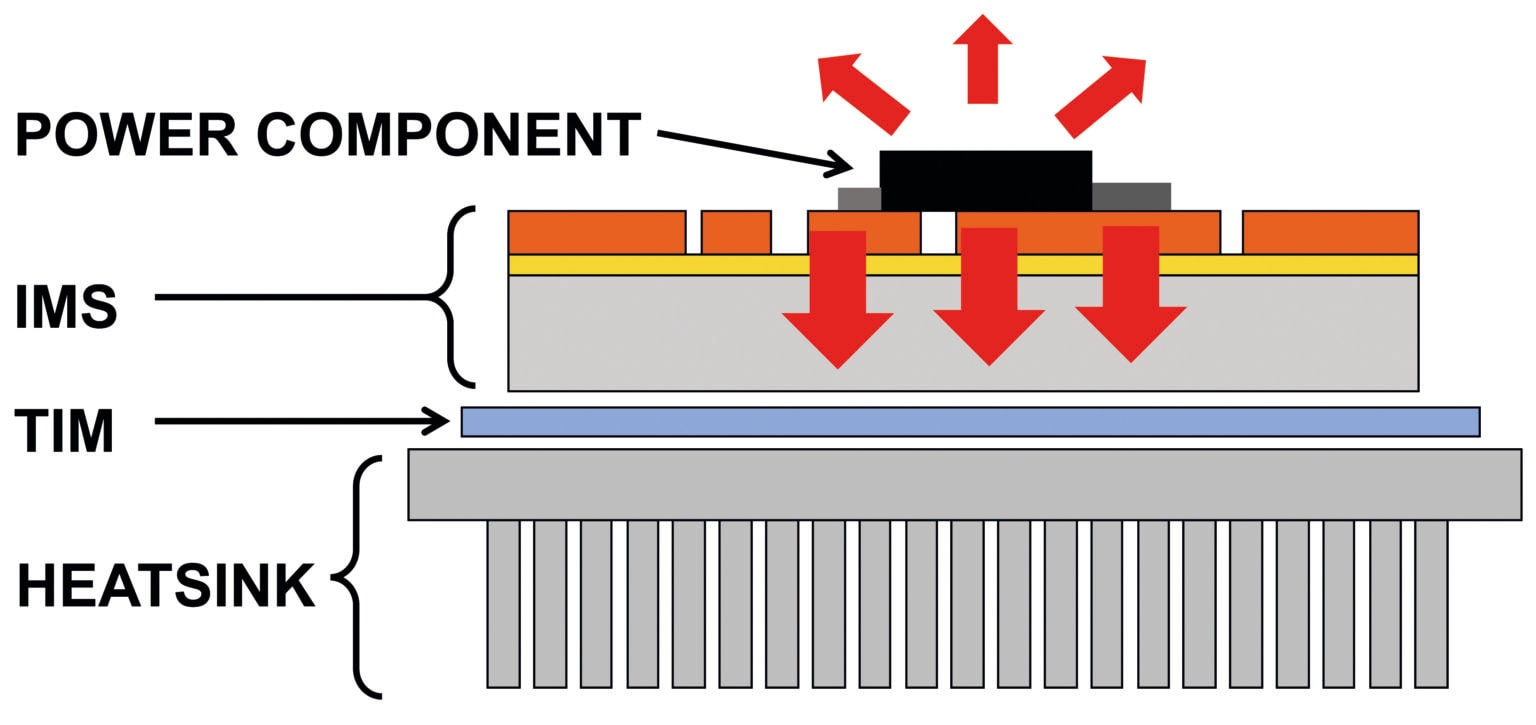

This new range of Thermal Interface Materials (TIMs) offer higher performance in smaller spaces requiring a quick, effective, and cost-efficient heat-transfer both within and out of today’s highly compact Electronic Power Modules. Well-designed heat-management concepts, based on Isolcopper, address two major concerns for power electronics:

1) Providing high dielectric strength (electrical isolation up to 6KV at 100m thickness)

2) Delivering ultra-low thermal resistance for quick heat spreading and removal

Product Range

Applications

Power electronics, electronic power modules in solar inverters, windmills, truck gear boxes, high power LED lighting, AC/DC converters. Industrial power electronics managements, in welding machines and robot drives. Electric Vehicles (EV) for Power Train and On-Board-Charger.